Part 2: Changing Column Inner Diameter with Constant Flow Rate

Guest Author: Dr. Jeff Layne

Guest Author: Dr. Jeff Layne

Welcome back to this article series on the effects of changing column inner diameter on LC-MS applications. Well, let’s be fair, we are using LC-MS to illustrate our discussion, but the concepts we cover apply equally to LC-UV applications.

So, in the last article we examined how changing the column ID while adjusting the flow rate proportionally to maintain the same linear velocity would affect peak height response using a simple LC-MS gradient application. In that example, we found that moving from 4.6 mm to 3.0 mm resulted in almost a doubling of peak height response, which was fantastic from a signal sensitivity perspective. However, when moving from 3.0 mm to 2.1 mm, it resulted in a more modest 7 % increase in peak height response. This may be due to the effects of system dwell volume on the performance of the 2.1 mm column, or perhaps in the nature of band broadening within the source of the MS itself, or it may simply be due to a small sample size and we need to look at more test probes. By adjusting our flow rate proportionally, we also maintain a (relatively) constant retention time as well. So that brings us to the topic of the current article: effect of changing column inner diameter while holding the flow rate constant.

In the last article, we scaled the flow rate to maintain a same linear velocity through each column inner diameter, using 1 mL/min, 0.43 mL/min, and 0.2 mL/min for the 4.6 mm, 3.0 mm, and 2.1 mm columns, respectively.

For this example, we are going to choose a single flow rate that can be considered middle-of-the-road for many LC-MS methods: 0.5 mL/min. That flow rate is well within the acceptable range of almost any reasonable modern MS source, and the resulting linear velocity is not too fast for most 2.1 mm columns and not too slow for 4.6 mm columns. We are using the same media (Kinetex 2.6 µm C18) with a water/acetonitrile/0.1% formic acid gradient from 5 – 95% B over 5 min. Our test probe is 17-alpha-OH-progesterone, and our system is an Agilent 1200 LC stack ahead of an API 4000™ MS system (SCIEX). We are bypassing the heating block to minimize extra-column dwell volume.

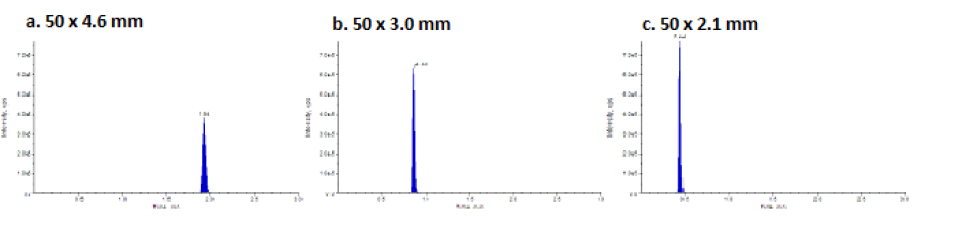

Representative chromatograms are in Figure 1, below. You can see that, as the column ID is decreases, we get a progressive increase in peak height response. Going from the 4.6 mm column (Figure 1.a) to the 3.0 mm column (Figure 1.b), peak height increases from 3.38e5 to 6.36e5, an increase of 88 %. Next, moving from the 3.0 mm to the 2.1 mm column (Figure 1.c), it increases from 6.36e5 to 7.76e5, an increase of 22 %. Overall, this data is similar to what was seen in the previous example when we were scaling the flow rate proportionally, with the greatest benefit going from 4.6 mm to 3.0 mm, and a more modest increase moving from the 3.0 mm to the 2.1 mm column.

Figure 1: Effect of changing column ID while holding flow rate constant

The significant difference is that now, without scaling the flow rate, there are substantial changes in retention times and back pressures as we move to different column IDs, while holding the flow rate at 0.5 mL/min (see Table 1). If the flow rate is held constant and column ID is decreased, the linear velocity of mobile phase through the columns increases significantly, leading to dramatic increases in pressure (from 78 Bar for the 4.6 mm column to 243 Bar for the 2.1 mm) and marked shifts in retention (1.94 min for the 4.6 mm to 0.44 min for the 2.1mm).

Table 1: Effect of changing flow rate on peak height response, system pressure, and retention time

Make sure you check back for the next article in of this series, as we attempt to distill the information from the first two articles and come up with a reasonable rationale to aid in column and mobile phase optimization. As you can see, it will be a balancing act between peak height response, retention, and pressure.

Make sure you check out the first article, “Changing Column Inner Diameter While Adjusting Flow Rate”, if you missed it!

Looking to improve your HPLC analysis. Check out the HPLC troubleshooting guide for the latest tips and tricks for LC analysis.